Servitization: The Business Buzzword Explained (and Why You Should Care)

Servitization: From Product Centric To Service Centric

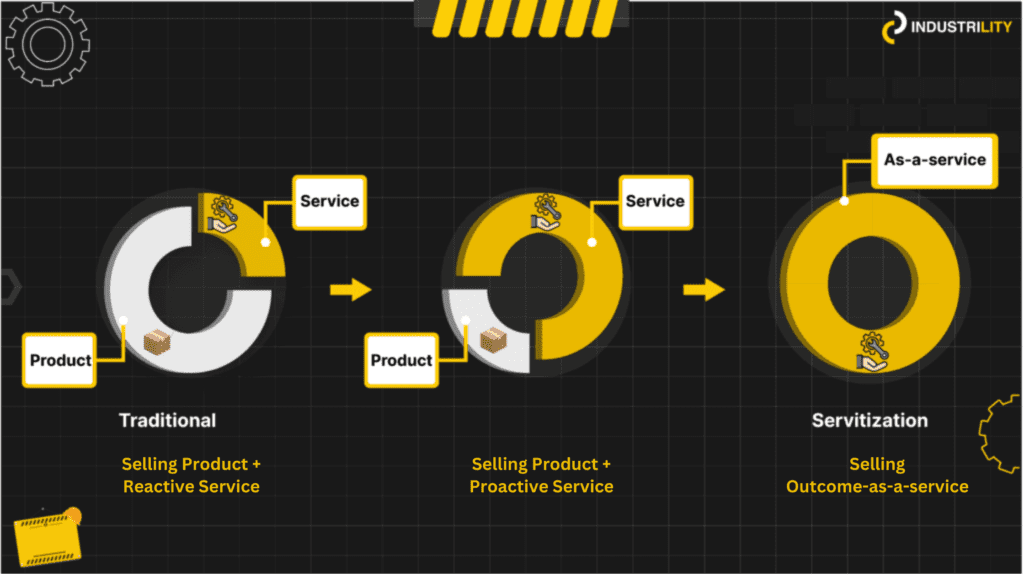

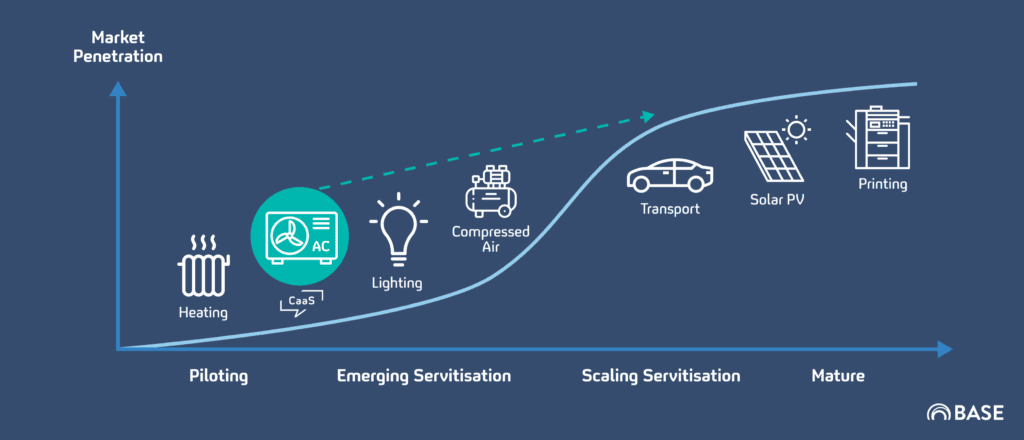

For decades, the manufacturing landscape thrived on a simple principle: sell machines/products. Companies built their success on churning out high-quality equipment and machinery, leaving after-sales support as an afterthought. However, the tide is turning. Servitization is a future-focused approach that revolutionizes this model by transforming businesses from product-centric to service-centric. In this blog, we’ll explore the concept of servitization, the role of digital technologies and data, and how it can help companies make this transformation successful.

The Power Of Data & Customer Loyalty Loop

Data and Digitalization isn’t just numbers; A clear strategy of the right data, purpose built technology for customer connection and achieving economies of scale is the key to implementing a successful servitization strategy.

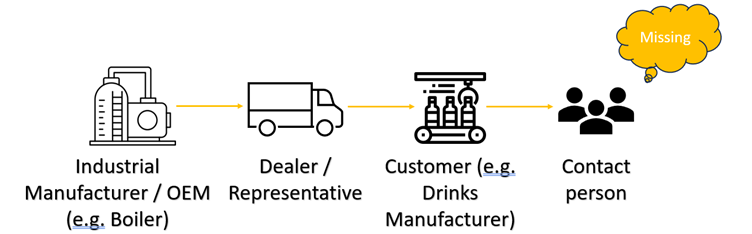

One of the keys to successfully implementing servitization is effectively understanding your installed-based data. Installed base data encompasses a wealth of information about the products and equipment a company has already sold and deployed at customer locations. This data, for connected or unconnected assets, provides insights into the status, performance, and usage patterns of these assets. More than 90% of the installed base is often unconnected and there is a massive opportunity to climb the ladder of servitization within the current installed base. Creating a map of your installed base is often the first step on this journey.

Leveraging This Data Is Essential For Several Reasons:

- Predictive Maintenance: Analyzing asset data (equipment status and performance) through IoT enables remote monitoring and proactive maintenance. This prevents costly downtime for customers and enhances their operational efficiency.

- Customized Solutions: Installed base data captured during various touchpoints (installation, inspection, service) provides a deep understanding of customer needs. This allows for tailor-made service packages that address specific client requirements and deliver a personalized experience.

- Performance-Based Contracts: Servitization often involves contracts where payment is tied directly to equipment performance. Detailed asset data is critical for verifying and reporting on these performance metrics accurately. Furthermore, advancements in e-commerce, payments, innovative financing, and IoT facilitate such models at scale.

- Continuous Improvement: Data analysis provides valuable insights into product performance and reliability in real-world scenarios. Companies can leverage this information to continuously improve product design and service offerings for future iterations.

Get closer to your customer first

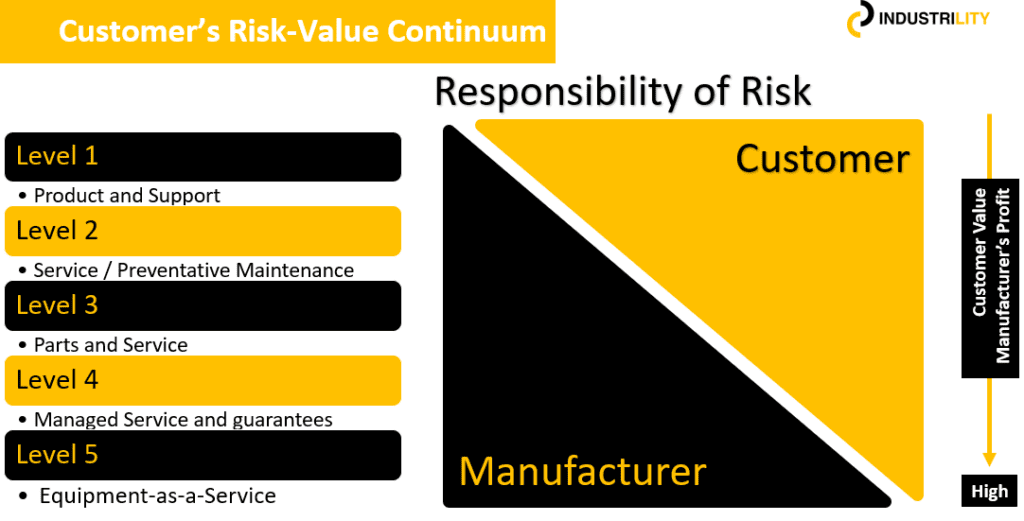

Customer's Risk Value Continuum

The Customer’s Risk Value Continuum is a framework used to understand customer decision-making when evaluating product-service offerings. It considers the level of risk a customer perceives when adopting a new solution and the value they expect to receive.

Here’s how it applies to servitization:

- Low Risk, Low Value: This segment represents customers who are comfortable with traditional product-based models and see limited value in additional services.

- Low Risk, High Value: These customers may be open to some basic services, such as installation or warranties, that provide added value without significant upfront commitment.

- High Risk, Low Value: This quadrant signifies customers hesitant to embrace new service models due to perceived risks. Building trust and clearly communicating the benefits of servitization is crucial for this segment.

- High Risk, High Value: These customers recognize the potential value proposition of servitization but require clear justification on how it mitigates the perceived risks and delivers substantial benefits.

By understanding the Customer’s Risk Value Continuum, businesses implementing servitization can tailor their offerings and messaging to resonate with different customer segments.

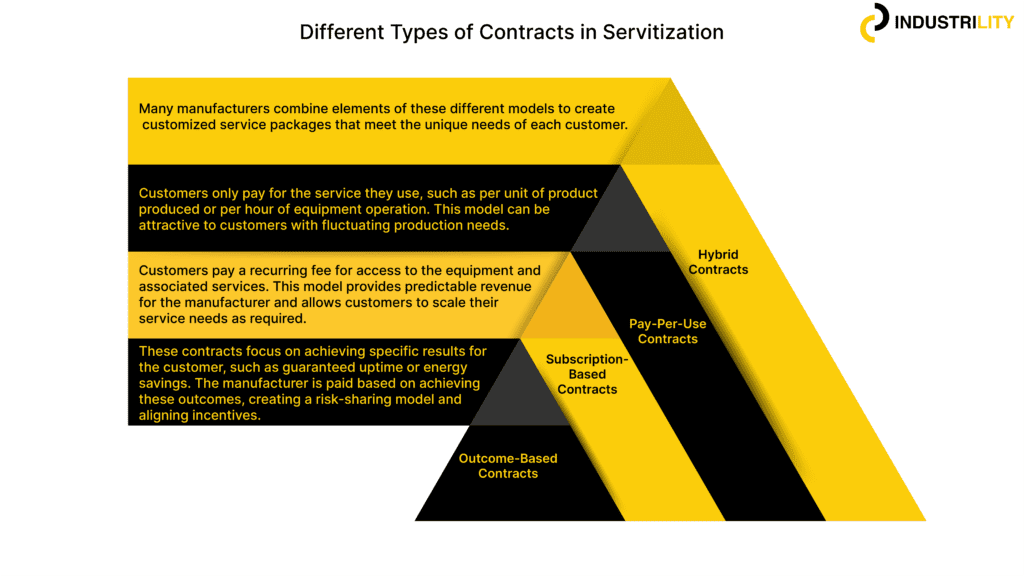

Different Types Of Contracts In Servitization

Moving from a product-centric approach to a service-centric one requires a shift in how contracts are structured. Here are some common types of contracts used in servitization:

- Outcome-Based Contracts: These contracts focus on achieving specific results for the customer, such as guaranteed uptime or energy savings. The manufacturer is paid based on achieving these outcomes, creating a risk-sharing model and aligning incentives.

- Subscription-Based Contracts: Customers pay a recurring fee for access to the equipment and associated services. This model provides predictable revenue for the manufacturer and allows customers to scale their service needs as required.

- Pay-Per-Use Contracts: Customers only pay for the service they use, such as per unit of product produced or per hour of equipment operation. This model can be attractive to customers with fluctuating production needs.

- Hybrid Contracts: Many manufacturers combine elements of these different models to create customized service packages that meet the unique needs of each customer.

The Future Of Servitization

The future of servitization is inextricably linked with the rise of Industry 4.0 and the Industrial Internet of Things (IIoT). These technologies are transforming the way manufacturers gather and analyze data.

Sensors embedded in machinery can provide real-time insights into performance metrics, allowing for predictive maintenance. This proactive approach minimizes downtime and optimizes equipment lifespan. Additionally, data analytics can be used to personalize service offerings and tailor solutions to individual customer needs.

The future of servitization is intertwined with several key trends:

- The Rise of the Outcome Economy: Customers will increasingly pay for the outcomes delivered by the equipment, not just the equipment itself.

- Data-Driven Servitization: Advanced analytics will play a crucial role in optimizing service offerings, predicting equipment failures, and providing proactive maintenance.

- AI-Powered Services: Artificial intelligence will be used to automate service delivery, personalize customer experiences, and develop predictive maintenance models.

Industrilty’s after-sales app platform and consulting services enables equipment manufacturers to launch, manage and scale their aftersales function, build a special customer link building a customer intimacy, improving superior customer satisfaction, better brand reputation; All of this without being a big and long IT project.

Conclusion

The future of manufacturing is all about building strong customer relationships and delivering value beyond the product itself. Servitization offers a powerful path to achieve this, but navigating the transition requires a strategic approach. Industrility stands ready to be your partner in this exciting journey. From leveraging data for predictive maintenance to crafting customized service packages, it can equip you with the tools to build lasting customer loyalty and achieve long-term success in the ever-evolving manufacturing landscape. Hence, by leveraging installed base data and partnering with specialized software development firms, manufacturers can enable the full potential of servitization.

– Achint Varia