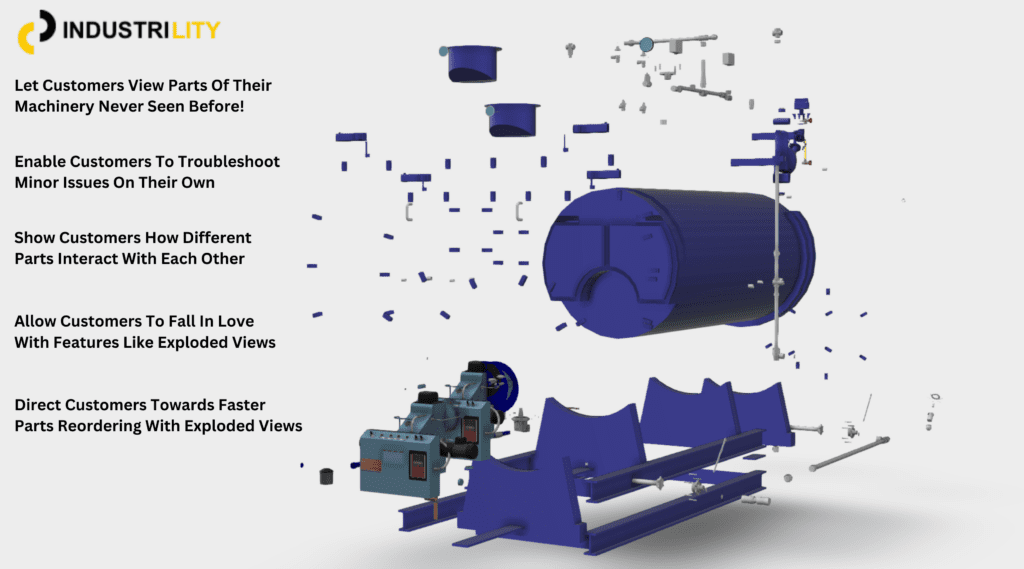

5 Benefits of Exploded Machinery Views: How Machine Manufacturers Can Improve Customer Experiences Easily

In today’s rapidly advancing industrial landscape, Original Equipment Manufacturers (OEMs) are constantly seeking innovative ways to enhance their operations, improve efficiency, and increase profitability. One such innovation that has proven to be invaluable is the use of exploded machinery views. An exploded view is a diagram, picture, or technical drawing of an object that shows the relationship or order of assembly of various parts. For OEMs, the ability to have exploded views of their machinery offers several significant benefits, which are outlined below.

1. Enhanced Maintenance and Repair Efficiency

Exploded machinery views provide a detailed visualization of every component within a machine, showing how each part fits and works together. This level of detail is crucial for maintenance and repair activities. Technicians can quickly identify the exact part that needs attention, understand its relationship with other components, and access the necessary information for disassembly and reassembly. This not only reduces the time required for repairs but also minimizes the risk of errors, leading to more efficient and effective maintenance processes.

By having precise instructions and clear visuals, maintenance teams can perform their tasks with greater confidence and accuracy, ensuring that machinery downtime is minimized and productivity is maximized. This efficiency translates to cost savings for OEMs, as less time and fewer resources are spent on maintenance activities.

2. Improved Parts Identification and Ordering

One of the common challenges faced by OEMs is the incorrect identification and ordering of parts. This often leads to delays in repairs and increased costs due to the return and exchange of incorrect parts. Exploded views address this issue by providing a comprehensive and detailed look at each component, complete with part numbers and descriptions.

With this information at their fingertips, OEMs can ensure that the correct parts are identified and ordered the first time around. This not only streamlines the ordering process but also reduces the inventory costs associated with holding incorrect or excess parts. Furthermore, it enhances customer satisfaction, as clients receive the right parts quickly and efficiently.

3. Streamlined Training and Knowledge Transfer

Training new technicians and ensuring the transfer of knowledge within an organization can be challenging, especially when dealing with complex machinery. Exploded machinery views serve as an excellent training tool by offering clear and detailed visuals that can be used to educate new employees about the structure and function of machinery.

These visual aids can significantly shorten the learning curve for new technicians, allowing them to become proficient more quickly. Moreover, they serve as a valuable reference for experienced technicians, providing a quick and easy way to refresh their knowledge. This streamlined training process ensures that OEMs maintain a highly skilled workforce capable of maintaining and repairing machinery effectively.

4. Enhanced Customer Support and Service

For OEMs, providing exceptional customer support and service is crucial for maintaining a strong reputation and fostering customer loyalty. Exploded machinery views enable OEMs to offer superior support to their clients by providing detailed diagrams and instructions that can be shared with customers.

When clients encounter issues with their machinery, having access to exploded views allows them to better understand the problem and communicate more effectively with support teams. This not only speeds up the troubleshooting process but also empowers customers to perform minor repairs and maintenance tasks on their own, reducing their reliance on OEM support. As a result, OEMs can focus their resources on more complex issues and provide higher quality service overall.

5. Facilitated Product Development and Innovation

Exploded machinery views are not only valuable for maintenance and support but also play a crucial role in product development and innovation. These detailed diagrams provide engineers and designers with a comprehensive understanding of how each component interacts within the overall system. This insight is essential for identifying areas for improvement, optimizing designs, and developing new and innovative machinery.

By using exploded views during the design and development stages, OEMs can ensure that their products are not only efficient and reliable but also easy to maintain and repair. This forward-thinking approach can lead to the creation of more advanced and competitive machinery, helping OEMs to stay ahead in a highly competitive market

Take A Look

Yes My Customers Need a 360 degree View Of Their Machinery!

Talk to us to explore Parts implementation in under 8 weeks

Conclusion

In conclusion, the ability to have exploded machinery views offers OEMs numerous benefits, from enhancing maintenance and repair efficiency to improving parts identification and ordering, streamlining training and knowledge transfer, enhancing customer support and service, and facilitating product development and innovation. As OEMs continue to modernize and embrace new technologies, the value of exploded views cannot be overstated. These detailed visualizations are a powerful tool that enables OEMs to optimize their operations, reduce costs, and ultimately increase profitability.’ – Jinesh Varia, CEO and Founder, Industrility.com