How PDC Machines Digitized Their Aftermarket to Unlock Revenue Growth

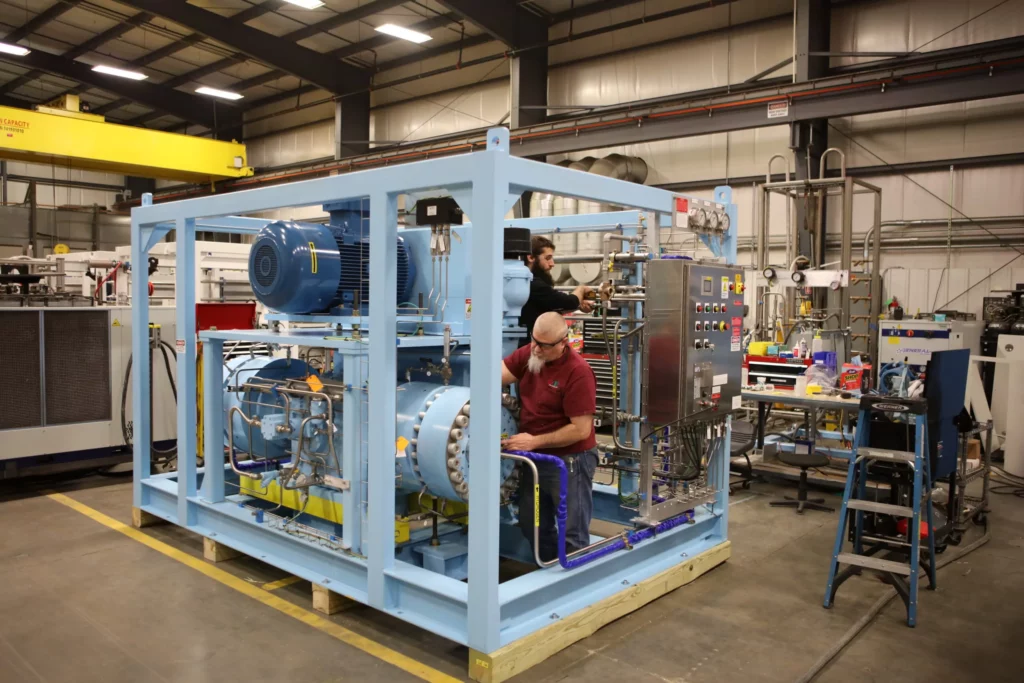

At PDC Machines, the real challenge was the outdated, manual aftermarket processes that slowed down their operations. As a global leader in diaphragm compression technology serving mission-critical sectors like hydrogen mobility and the industrial gas market, PDC Machines faced increasing complexity as their customer base expanded worldwide. Their legacy systems, relying on spreadsheets, USB drives, and email, could no longer provide the speed, accuracy, or reliability their customers demanded.

“Manual chaos was holding us back,” said Peter Tarnawskyj, Senior Business Segment Manager for the Aftermarket at PDC Machines. “We were losing efficiency, and that meant losing revenue.”

The Challenge: Scaling Service Without Losing Control

With over 2,000 compressors in the field, PDC Machines confronted three major challenges:

- Lack of real-time visibility into their installed base

- An inefficient and error-prone spare parts ordering process

- An urgent need to scale after-sales support while maintaining high standards of service

Their customers demanded more than just access to spare parts. They needed reliable machine uptime, timely technical support, and quick access to accurate documentation.

The Industrility Solution: A Customer Portal Built for Uptime and Efficiency

To overcome these challenges, PDC Machines partnered with Industrility to launch MyPDCMachines.com, a white-labeled, self-service customer portal powered by Industrility’s cloud-based aftermarket platform.

At the heart of this transformation is Industrility’s Operational Digital Twin, a consolidated, customer-facing interface that brings all critical documentation and tools into one easy-to-navigate portal.

Key features of the new portal include:

- Spare Parts and Digital Bill of Materials:

Customers can quickly identify and order the correct spare parts with confidence through an interactive digital catalog.

- Service and Maintenance Tools:

Proactive scheduling, integrated field service workflows, and streamlined technical support improve uptime.

- All Critical Documentation in One Place:

Three-dimensional computer-aided design files, user manuals, commissioning reports, and dimensional diagrams are now instantly accessible.

- Installed Base Visualization:

A mapped view of all machines sold provides PDC Machines with a comprehensive global fleet overview. - QR Code-Based Asset Tracking:

Each compressor is tagged with a unique QR code, enabling field teams to instantly access asset-level documentation, service history, and maintenance timelines.

“Thanks to Industrility, MyPDCMachines is a product of our commitment to customer service. It simplifies maintenance and reduces our customer’s total cost of ownership,” said Bree McQuillan, Chief Executive Officer at PDC Machines.

The Results: From Manual Chaos to Measurable Growth

Since launching the portal, PDC Machines has realized impressive results:

- Increased service and spare parts revenue by 50 percent annually

- Consistently executed planned maintenance programs with precision

- Strengthened customer satisfaction and brand loyalty

By empowering customers to self-serve critical functions, the portal has reduced unplanned downtime and eliminated the need for back-and-forth communications.

A Digital-First Future for Aftermarket in Equipment Manufacturing

PDC Machines exemplifies what original equipment manufacturers can achieve by digitizing their aftermarket operations. Transitioning from reactive processes to proactive service delivery has led to improved operational efficiency and unlocked new revenue streams.

Ready to Build Your Own Aftermarket Portal?

Industrility helps OEMs launch self-service portals that reduce manual effort, boost revenue, and create better customer experiences.