Boiler Manufacturer Unlocks Aftermarket Growth with Installed Base AI

Executive Summary

A leading industrial boiler manufacturer, with a long history of market leadership, partnered with Industrility to reclaim its aftermarket dominance and drive new revenue growth. The core challenge was severe data fragmentation; critical information on their installed base was scattered across disconnected ERP systems, service spreadsheets, public regulatory inspection certificates, Start-up reports, PDF reports, regional databases and distributor data. This created significant operational friction and revenue leakage.

By partnering with Industrility, the manufacturer built an “Installed Base Golden Record”, a single source of truth for every piece of equipment. Leveraging Industrility’s AI-powered platform, the project aggregated these disparate data sources, cleansed the information, and used machine learning to forge connections between isolated records.

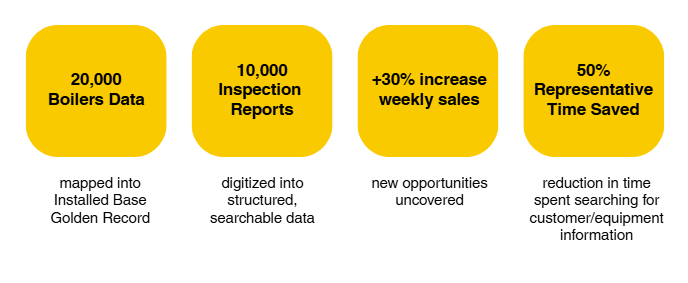

The results were immediate and profound. The company achieved complete visibility of its installed base, empowered its sales teams with a 360-degree customer view, and immediately uncovered new revenue streams, positioning itself for a new era of aftermarket growth.

Customer Background

For decades, the manufacturer has been a premier name in industrial boilers, with a reputation for engineering excellence. Their go-to-market strategy relies on a widespread network of authorized representatives, which allowed them to build a substantial market presence across diverse industries.

However, this decentralized model inadvertently created deep-rooted data challenges. Critical information about the end customer, equipment status, and service history was often trapped in local, siloed systems. This prevented the manufacturer from achieving a clear, centralized understanding of its own assets in the field.

The Challenge: Data Fragmentation and Aftermarket Blind Spots

The inability to see their full installed base created a cascade of business challenges that hampered growth. The organization was operating with significant blind spots, making proactive management nearly impossible.

- Pervasive Data Silos: The company’s data landscape was a maze of disconnected systems. To get a complete picture of a customer, a team member had to manually consult multiple platforms. Answering a simple question like, “What is the full history of this boiler?” required hours of manual, often incomplete, research.

- Significant Revenue Leakage: Without a unified view, customers would inevitably fall “off the radar” after their initial warranty period expired. This led to substantial revenue leakage as service contracts lapsed and upgrade opportunities were missed.

- Ineffective Partner Coordination: The data gap made it difficult to support their vital representative network. The manufacturer could not easily identify which customers needed attention or equip reps with the data needed for strategic, consultative sales conversations.

The bottom line was clear: operational inefficiencies were leading to a poor customer experience, eroding loyalty, and leaving significant aftermarket revenue on the table.

The Solution: Building an Installed Base Golden Record with AI

Industrility’s approach was to build a clean, enriched master database from the ground up. This “Golden Record” would serve as the single source of truth for the entire organization.

Our Four-Phase Process:

- Data Collection & Aggregation: First, we consolidated data from every available source into a complete data lake. This included structured data from ERPs and service systems alongside unstructured data from PDFs, public databases, and internal Excel files.

- AI-Powered Data Cleansing and Linking: This is where Industrility’s core technology created transformative value.

a. Using advanced AI that digitally reads documents, we processed thousands of PDF inspection reports, extracting previously inaccessible information like contact names, phone numbers, and inspection dates.

b. Our machine learning algorithms then intelligently linked related records across all systems, even without perfect matches. This created a complete, 360-degree view of each asset. - Contextualization & Enrichment: Once linked, the unified data was enriched with external services like Google Maps and Dun & Bradstreet. This process validated addresses and contacts, creating an accurate and contextually rich aftermarket CRM.

- Ongoing Data Governance: The Golden Record is maintained on Industrility’s SaaS platform with continuous data governance, ensuring the information remains accurate, trustworthy, and valuable over time.

Measurable Outcomes and Business Impact

The project delivered a significant return on investment and catalyzed a cultural shift toward data-driven decision-making.

- A Unified, Searchable Asset Database: The manufacturer now has a complete, enriched record of all boilers and customers, accessible in real-time through an intuitive dashboard.

- Reduced Revenue Leakage: By identifying dormant customers, the sales team immediately re-engaged them, leading to a surge in new service contracts and parts sales.

- An Empowered Distributor Network: Representatives now have centralized, accurate data, allowing them to act as strategic partners and

Customer Testimonial

The project’s success was best summarized by the client:

“Industrility helped us realize our 10-year vision of delivering a digital experience for our industrial boiler rooms in a matter of weeks. Truly a trusted partner in our success.”

–Vice President of Account Management and Strategy

Conclusion: A Blueprint for Aftermarket Success

By transforming fragmented data into a strategic asset, the boiler manufacturer has reclaimed its aftermarket leadership and built a foundation for future growth.

Industrility’s AI-powered platform provided the engine for this change. It demonstrates that a deep understanding of the installed base is the key to unlocking hidden revenue, empowering sales teams, and building lasting customer loyalty in the industrial sector.