Why Generative AI Is the Aftermarket Game-Changer Industrial Manufacturers Can’t Afford to Ignore

In today’s industrial and commercial machinery markets, one thing is clear: aftersales isn’t just an opportunity — it’s the battleground for long-term profitability.

Yet most manufacturers are struggling to win this war.

The Aftersales Crisis No One Wants to Talk About

Let’s start with some hard truths:

-

Industrial equipment manufacturers often rely on 30-50% of their total profit from aftermarket parts, service, and digital upgrades.

-

Yet over 60% of companies have no complete view of their installed base, leading to missed service contracts, unclaimed parts revenue, and shrinking margins.

-

Many are still buried in legacy ERPs, siloed data, aging parts catalogs, and tribal knowledge that retires along with the workforce.

McKinsey reports that aftersales and service can be 2 to 5 times more profitable than original equipment sales, yet companies consistently underinvest in digital capabilities to capitalize on it. (Source)

Meanwhile, Bain & Company highlights that manufacturers who digitize their service operations can increase EBITDA by 25% or more. (Source)

In its first annual report as a standalone company (2025), GE Aerospace revealed that aftermarket services account for nearly 70% of total revenue. (Source)

That’s not an outlier — it’s the future. Whether you build jet engines, CNC machines, hydraulic systems, or compressors, aftersales is your core profit engine.

Why the Problem Runs Deep

The challenges aren’t superficial. They’re structural and endemic:

Fragmented Systems: Decades of ERP sprawl — Oracle here, SAP there, some IFS or Epicor in between — make a single source of truth for assets, parts, or customer service nearly impossible.

Endless ERP Migrations: A typical ERP consolidation takes 18–36 months — and often resets or becomes out-dated before it completes.

Workforce Drain: As veteran technicians retire, they take critical tribal knowledge about machines, configurations, and common failures with them.

Parts Complexity: Manufacturers support machines in the field for 15–25 years, yet BOMs, CAD files, and parts diagrams are scattered across systems, generations, and geographies.

Customer Expectations Are Soaring: Amazon-style expectations are here. Customers want part lookup by photo, same-day quotes, self-service dashboards — but the backend isn’t ready.

The result? Stalled service revenue, lost parts orders, costly technician errors, and poor customer satisfaction.

Enter Generative AI + Industrility: Leaping Over the Roadblocks

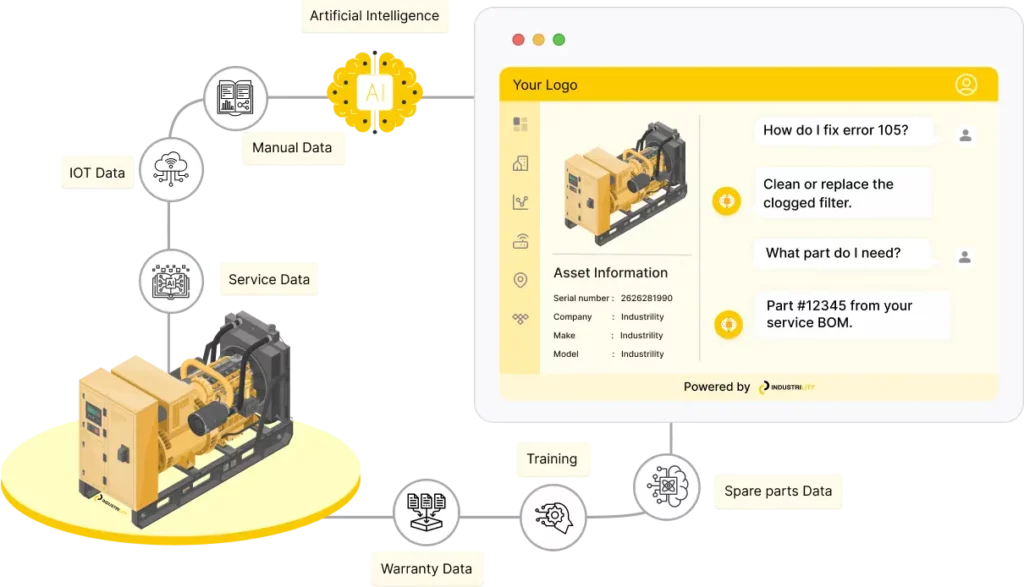

Generative AI is redefining what’s possible in the industrial aftersales space — and Industrility is at the forefront of this revolution and building a new AI operating system for Aftersales. Here is what’s coming in near future:

Installed Base Intelligence

AI agents reconcile fragmented (unstructured, structured, hand-written) records — serial numbers, site photos, 2D/3D CAD, service logs — into a unified machine profile, with dynamic lineage and real-world condition.

AI-Powered Service Agents

Technicians get on-demand assistance through conversational interfaces. Instead of flipping manuals, they ask:

“What’s the torque spec for this valve?”

“When was this component last replaced?”

Photo-to-Part Matching

Customers snap a photo. AI matches it to the correct part number — using a fusion of CAD, image libraries, and historical orders.

Aftermarket Opportunity Discovery

Generative AI agents analyze patterns and anomalies to suggest:

“This customer may need a replacement hydraulic kit in 90 days.”

“This unit is overdue for firmware calibration.”

Digital Memory for Machines

Each machine has a conversational, evolving memory — enabling service teams to know not just what the machine is, but where it’s been, and what it might need next.

The Results: Real EBITDA Gains

Let’s quantify it:

10–15% increase in parts sales from better catalog search and visual identification

20% faster service resolution time with Generative AI assistance

Up to 5X increase in service contract conversions with proactive opportunity detection

$2–5M annual uplift in EBITDA for mid-sized OEMs, per Industrility benchmarks

Manufacturers, the time to act is now...

Industrility isn’t building tools for yesterday’s problems. We’re creating the platform that turns Generative AI into aftersales ROI.

While others wait for ERP migrations to finish or attempt to “digitize” paper catalogs, Industrility enables:

Machine-Specific Digital Twins with real-world service history

Conversational interfaces for parts lookup, service questions, and work orders

Cross-platform integration that works with your existing tech stack — not against it

Every year you delay digitalizing your aftersales is another year your competitors pull ahead. Your machines are already in the field. Your customers are already searching. Don’t let complexity or legacy systems hold you back.

With Generative AI and Industrility, you can turn your service organization from a cost center into a scalable, predictable profit center.