Grow your Aftermarket With Industrial AI

The smartest AI aftermarket software for complex equipment, built to grow recurring revenue and modern customer experiences.

Why Aftermarket Matters?

A service-first approach is no longer optional for equipment manufacturers; it is the single biggest lever for long-term profitability and competitive advantage — accelerated with industrial AI.

Trusted by Manufacturers. Loved By All.

Managing over 10,00,000 Equipment assets with the power of AI.

All-in-One Aftermarket Platform

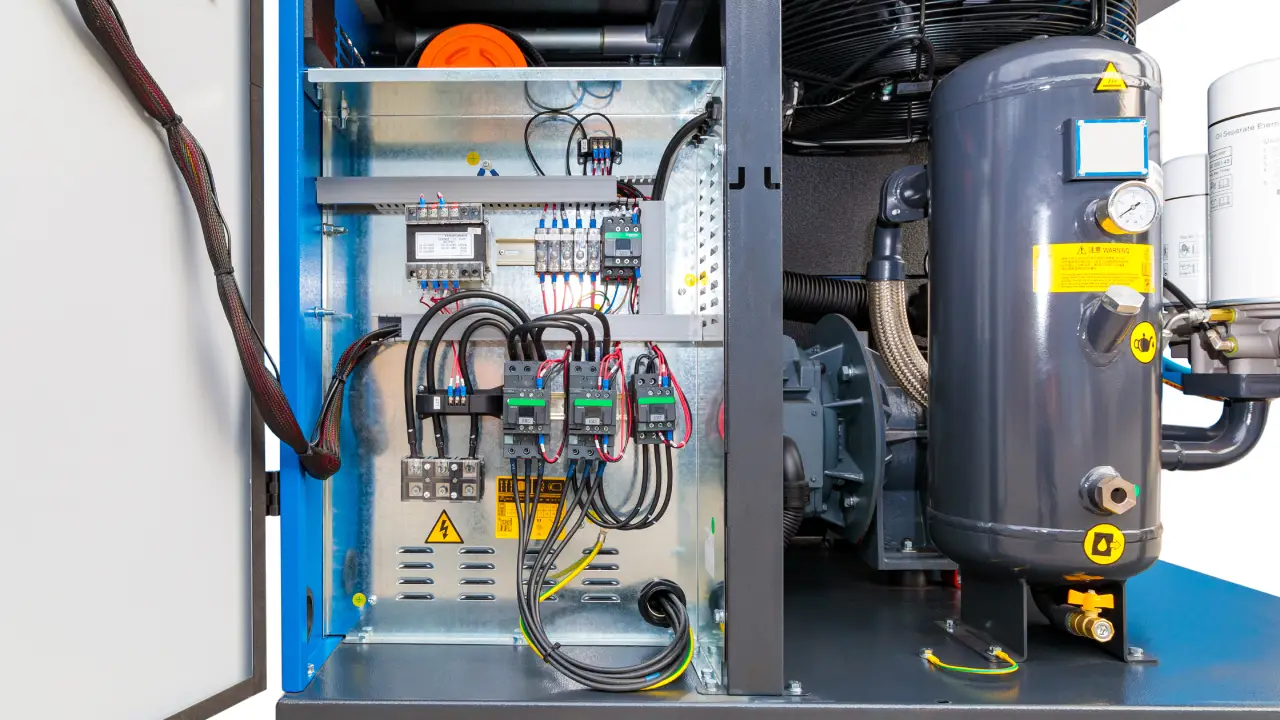

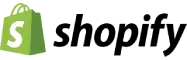

Installed Base Intelligence

The software platform manufacturers use to curate and manage their installed base with AI, enabling proactive customer service.

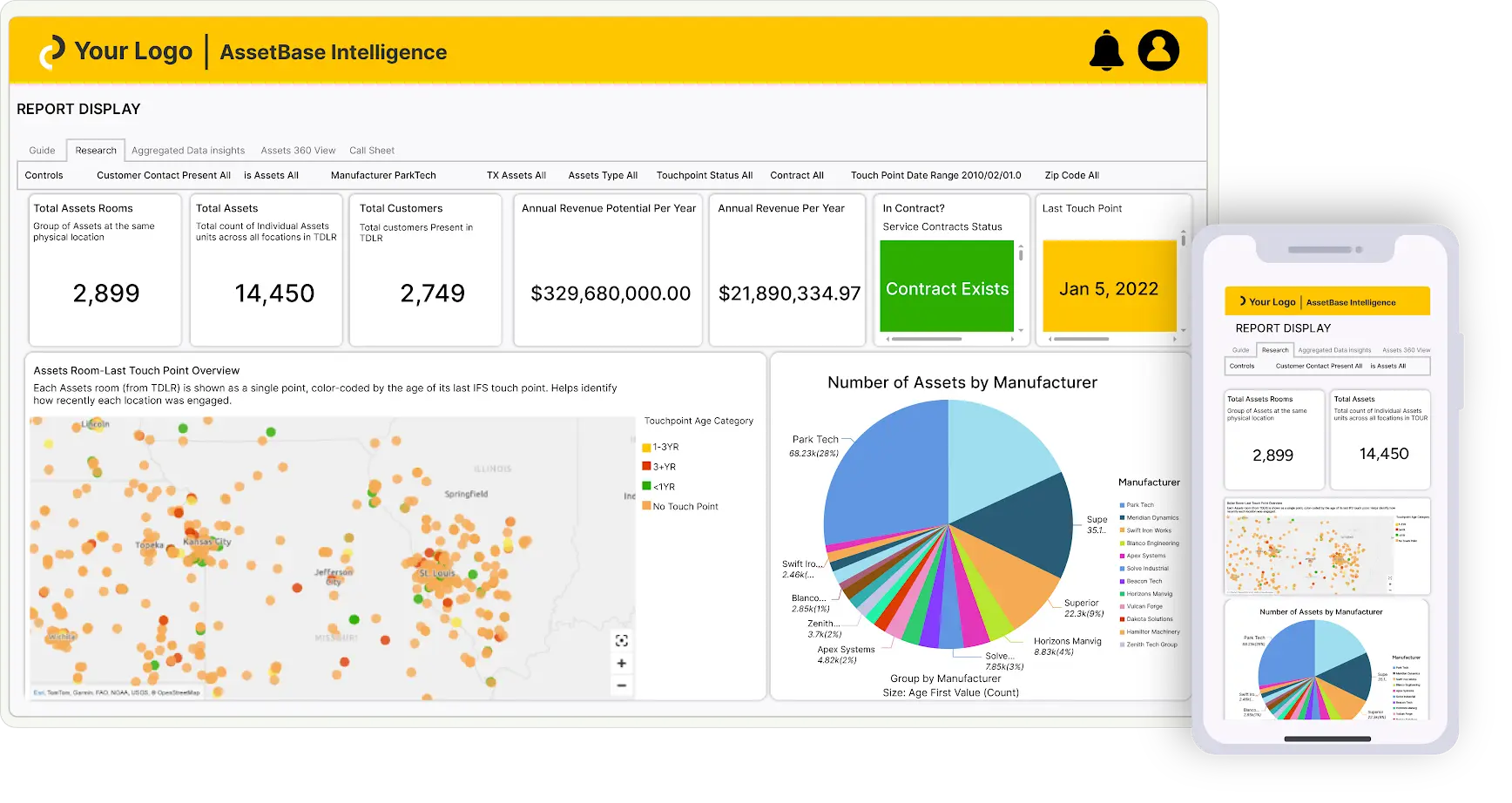

Parts Commerce

AI-enabled, hyper-personalised 3D parts catalogue and eCommerce with seamless B2B, B2B2B, and B2C quote-to-cash processes.

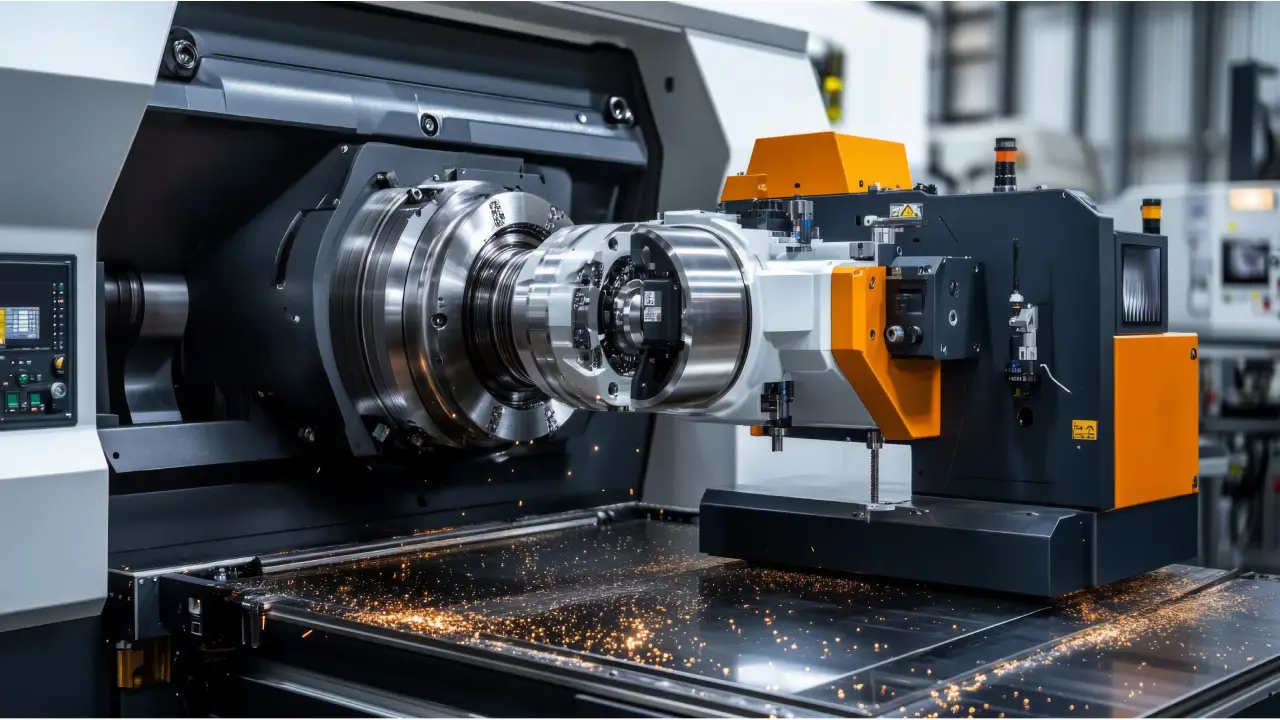

Purpose-built for forward-looking manufacturers of complex, made-to-order machinery.

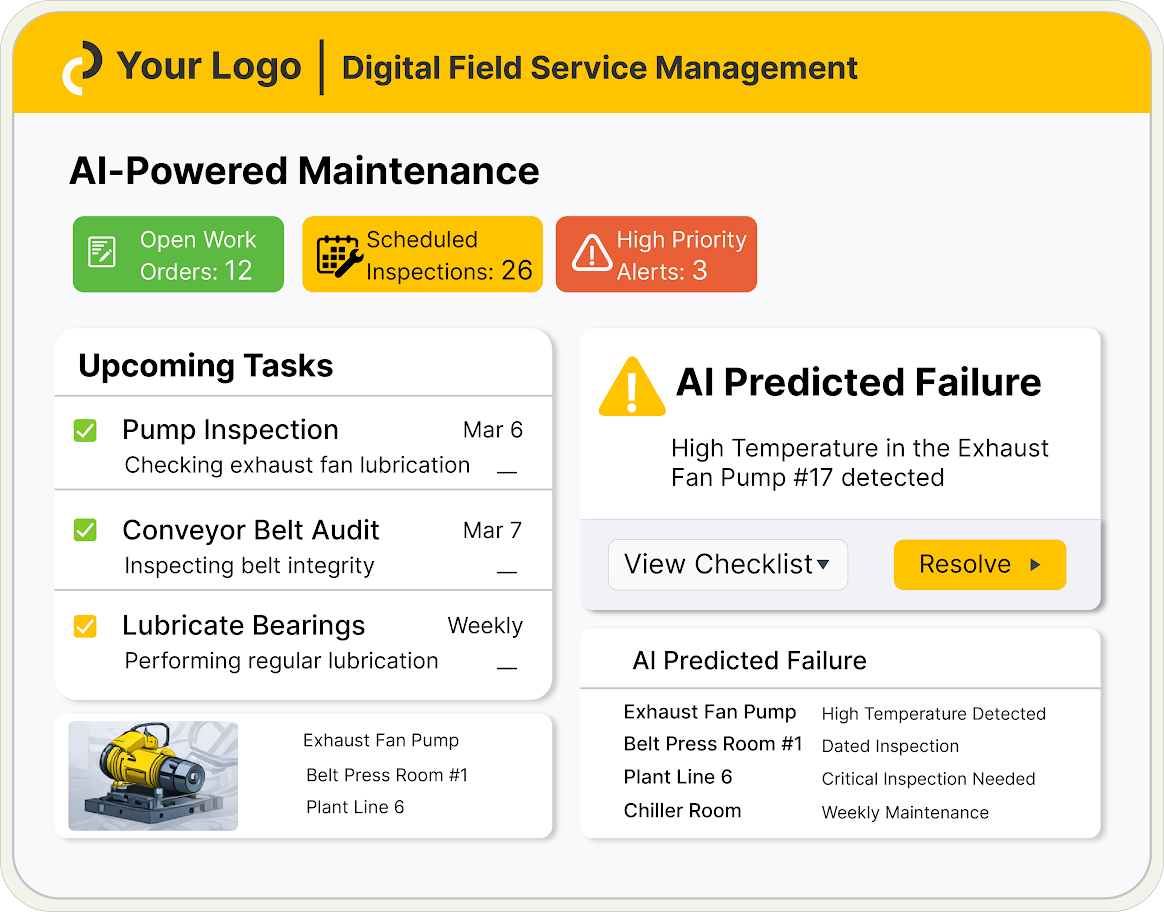

Maintenance Operations

AI-driven preventive and prescriptive maintenance that standardizes work orders, inspections, audits, training, checklists and field execution.

Remote Monitoring

Struggling to monetize and generate value from your IIoT data? You are not alone.

Turn live IIoT sensor data into predictive alerts, service actions, and parts recommendations with instant purchasing.

Move beyond basic alerts to true servitization of your business model through remote monitoring.

Machine Co-Pilot/TwinGPT

The industry’s first Industrial AI that enables manufacturers to offer a ChatGPT-style co-pilot for complex machinery.

- AI Agent for every machine

- AI Agent for parts ordering

- AI Agent for generating SOP and Service Tasks

Customer Service

The software platform manufacturers use to scale service, asset intelligence, and recurring revenue.

- Omni-channel support

- Cases & tickets

- Asset-linked support

- Digital warranty

- Dealer & asset scoring

- Sustainability tracking

Results You Can Measure

Industrility is not just a platform; it’s an investment with a guaranteed return. Our clients achieve significant, measurable improvements in their core business operations:

Platform You Can Trust

Enterprise-Grade Security & Compliance

Why Leading Manufacturers Choose Industrility

MyOEM Portal for Every Stakeholder

MyOEM Portal for Every Stakeholder

A hyper-personalized, branded asset portal tailored for customers, dealers, and partners — keeping you connected across every asset’s entire lifecycle.

AI-Driven Service Lifecycle Management (SLM)

AI-Driven Service Lifecycle Management (SLM)

Industrial AI that identifies service and parts opportunities, improves uptime, and increases aftersales profitability throughout the service lifecycle.

Complete Asset Lifecycle Management (ALM)

Complete Asset Lifecycle Management (ALM)

Servitization & Monetization

Servitization & Monetization

Industrility Customer Onboarding Timeline

From onboarding to impact in just two weeks!

Day 1–2

Kick-off & Planning

Kick-off meeting with project shareholders

Day 3–5

Data Integration

Import Installed Base and Asset data

Day 6–8

Platform Setup

Configure dashboards, user roles, permission

Day 9-14

Training & Go - Live

Conduct hands - on Training sessions

Testimonials

Bree McQuillan

“Industrility has been a trusted partner in building our MyPDC Machines portal. Their team helped us connect installed-base data to maintenance and parts, giving customers a seamless way to manage reliability and plan service. It’s elevated our aftermarket experience and supports our growth strategy.”

Brennan Morrow

“MyAstec has transformed how our customers manage their asphalt plant assets. With features like identifying parts in just three clicks, managing quotes in one place, and conducting asset-specific inspections, it provides a seamless, modern experience. Industrility has been an excellent partner in helping us bring this vision to life and deliver more value to our customers.”

Peter Tarnawskyj

“Industrility’s platform has allowed us to really integrate all our assets into one place, have available bills of materials and documentation at customers’ fingertips, and proactively connect with our end users. The team brings continuous innovation—adding features like QR code tracking and adapting quickly to our feedback—which makes them not just a technology partner, but a true consultant guiding our aftermarket journey.”

Patrick McCarthy

"Industrility is reimagining how manufacturers unlock value from their assets. Their bold vision and AI-first approach positions them to transform the industrial aftersales space and I am excited to support their journey. The team’s focus on solving real-world challenges in service lifecycle management is both timely and impactful, and I look forward to contributing to their success."

Uma Palaniappan

"Industrility is doing the right thing. You are bringing sophisticated AI-led solutions to Tier 2 and Tier 3 OEMs, who might otherwise not have the resources or expertise to do it on their own. That democratization of capability is incredibly important."

Why Industrial AI for Aftermarket?

1. What is an aftermarket solution, and why should my company use one?

Aftermarket solutions help industrial companies optimize their operations by streamlining data management, improving service delivery, and unlocking new revenue opportunities from their existing installed base. By integrating data from various systems, you gain valuable insights into performance, maintenance, and customer needs.

2. How do aftermarket solutions benefit OEMs and service providers?

Aftermarket software provides OEMs and service providers with real-time visibility into their installed base, enabling them to predict potential issues, improve customer satisfaction, and drive operational efficiency. This leads to reduced downtime, higher customer loyalty, and more profitable service contracts.

3. How does using an aftermarket solution improve customer retention?

By leveraging predictive analytics, aftermarket solutions help identify under-served customers and anticipate their needs, allowing businesses to provide proactive support, personalized aftermarket service, and timely maintenance. This builds trust and strengthens customer loyalty over time.

4. How do aftermarket solutions increase revenue opportunities for my business?

Aftermarket solutions provide insights into untapped opportunities, such as upselling and cross-selling additional services or products. By having a clearer understanding of your installed base and its needs, you can offer tailored solutions that boost revenue while enhancing customer satisfaction.

5. How do aftermarket solutions impact internal teams and workflows?

Implementing an aftermarket solution helps internal teams, including service and maintenance, to work more efficiently by providing access to centralized data. This allows for faster decision-making, improved collaboration, and optimized resource allocation, leading to higher productivity and lower operational costs.

6. What are the key benefits for decision-makers in using aftermarket solutions?

For decision-makers, aftermarket solutions provide a strategic view of operations, helping to optimize service delivery, reduce costs, and improve customer outcomes. They can make data-driven decisions that enhance service offerings, increase profitability, and align with long-term growth objectives.

7. How do aftermarket solutions help in reducing operational risks and downtime?

By predicting potential issues and streamlining maintenance scheduling, aftermarket solutions minimize the risk of unexpected breakdowns and costly downtime. This ensures a smoother, more efficient operation and reduces the impact of disruptions on both customers and business performance.

8. How can aftermarket solutions transform my organization's service delivery?

Aftermarket solutions help businesses deliver smarter, more efficient services by centralizing data, providing real-time insights, and automating key tasks. This improves the quality of service, enables faster response times, and enhances customer satisfaction—all contributing to long-term business success.

9. How does an aftermarket solution support sustainable growth for my company?

By enhancing the efficiency of service operations and unlocking new revenue streams from existing assets, aftermarket solutions enable sustainable growth. They provide the tools to continuously improve service delivery, optimize resources, and adapt to changing market demands.

10. What role does predictive maintenance play in aftermarket solutions?

Predictive maintenance is a key component of aftermarket solutions. It uses real-time data and analytics to predict when equipment is likely to fail, allowing for proactive repairs before costly breakdowns occur. This reduces downtime, extends asset life, and enhances overall service reliability.

Newsletter

Inspiring content, trends & news.

| Thank you for Signing Up |